- Home

- About us

-

Products

-

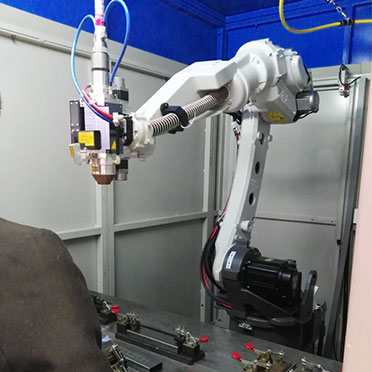

Profiled plastic laser welding machine 360 degree circular tube plastic laser welding machine Plastic laser welding machine for manipulator Temperature measuring closed loop plastic laser welding machine Double position plastic laser welding machine for manipulato Self welding plastic laser welding machine with welding Quasi synchronous laser plastic welder Synchronous plastic laser welding machine Strip light plastic laser welding machine On line laser plastic welding machine Two station manipulator welding machine Double station plastic laser welding machine

-

Fiber laser marking machine End pump laser laser carving machine CO2 laser marking machine Ultraviolet laser marking machine Online laser code printer Laser engraving machine for mould 3D laser laser carving machine Laser texturing machine for mold leather Laser marking machine for traceability system Portable laser marking machine Non standard laser marking machine

-

- Cooperative client

- News

- Network

- Message

- Contact us