8321u03pf8|20004BA6D256|bds289496167_db|article_category|content3|0xf3ffa31b02000000d606000001000f00

8321u03pfd|20004BA6article_category|content3

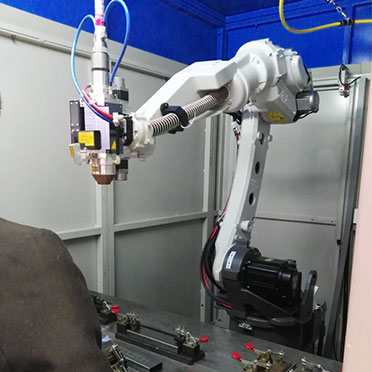

1. Energy real-time control and various waveform settings bring precision welding quality

2. High stability, high reliability, 24-hour stable operation

3. The energy distribution of welding spot is uniform, which is suitable for spot welding of various complex welds and various devices

4. It can meet the trajectory control of plane and special-shaped graphics such as welding points, lines and circles. The welding programming adopts trajectory programming, which is simple to operate and automatic in the welding process. The welding program can be modified, and the operation and modification authority can be set;

5. With higher electro-optic conversion efficiency, better beam quality and less maintenance cost, it is a perfect substitute for the existing lamp pumped YAG laser

6. CCD monitoring system, X / Y / Z / u worktable, rotary worktable and special automatic chemical fixture provide perfect processing scheme