Laser solder (Laser Soldering) has the following terms: laser reflux welding (Laser Reflow Soldering), laser tin bond welding (Laser Solder Bonding), laser ball planting (Laser Solder Bumping) but the principle of basic connection is the same. The connection is realized by heating the connection part with laser and melting the solder.

As a rapid development of laser tin welding technology in recent years, compared with the traditional electric soldering iron technology, laser welding technology is more advanced, heating principle is also different from the former, it is not simply to replace the heating part of the soldering iron. Laser is "surface exothermic", heating speed is very fast, while soldering iron is heating slowly by "heat transfer".

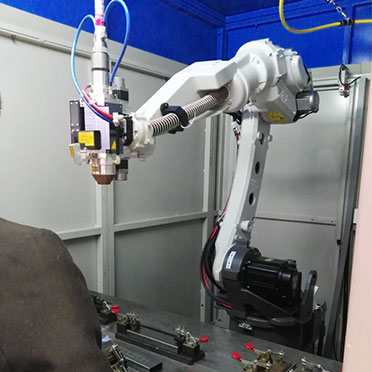

Laser tin welding process

1, laser irradiation to the welding site, to achieve solder melting temperature

2, supply tin solder, continue to irradiation

3, supply finished, continue irradiation to achieve welding

4, continue to irradiation, solder joint shaping

5, shaping finished, Turn off lase