8321u03pf8|20004BA6D256|bds289496167_db|article_category|content3|0xf3ffc71b02000000cb0a000001000500

8321u03pfd|20004BA6article_category|content3

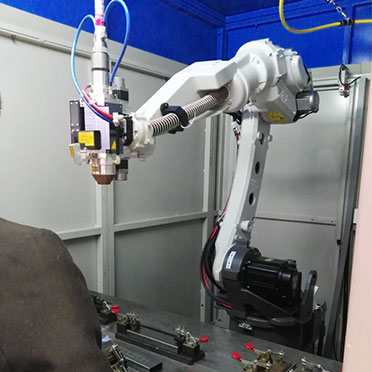

1. The equipment has compact structure, clear modules, stable performance, low failure rate and convenient maintenance

2. Non contact welding, small welding stress, small deformation, beautiful welding, high performance and energy saving

3. Air cooled heat dissipation is adopted. It is environmentally friendly and easy to maintain, which improves the stability and light quality of the equipment

4. The operation of the system is convenient and reliable. The LCD display is used as the man-machine interface, and the operation is intuitive and concise

5. Can weld a variety of different plastics together

6. Safe and pollution-free

7. Good air tightness and water tightness