8321u03pf8|20004BA6D256|bds289496167_db|article_category|content3|0xf3ffaf1b020000001f0a000001000700

8321u03pfd|20004BA6article_category|content3

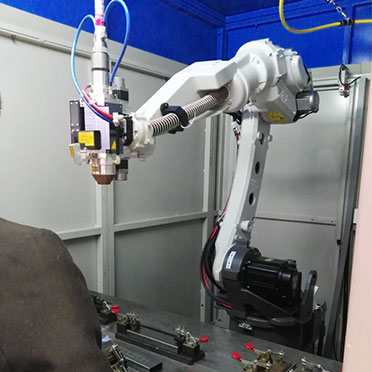

1. The integrated design integrates the laser, water tank and control part, with smaller floor area and low requirements for the site. It is equipped with mobile pulley. The station can be adjusted at any time according to the site requirements, which is convenient and flexible

2. The hand-held welding gun can be equipped with 5 meters, 8 meters and 10 meters of transmission optical fiber, which breaks through the limitations of the worktable and can reach a wider welding range. It is suitable for all kinds of complex welds and can weld any part and angle of the workpiece

3. Cooperate with the automatic wire feeding system to realize the welding of products with large seam width

4. Continuous laser mode, smooth weld transition, good welding quality, no fish scale, firm weld

5. The operation is simple, easy to learn, quick to start, the technical threshold of operators is not high, and the labor cost is saved

6. The welding heat affected zone is small, the yellow and black areas on both sides of the weld are small, and the overall deformation of the workpiece is small

7. The stacking height of weld surface is small, and there is no need for secondary grinding treatment, reducing labor and time cost

8. Low use and maintenance cost