introduce:

Metal laser welding: using high-energy laser pulses to locally heat the material in a small area, the energy of the laser radiation diffuses into the interior of the material through heat conduction, and the material is melted to form a specific molten pool, mainly for thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld, and no need for post-welding treatment Or as long as a single treatment is required, the welding seam quality is high, no pores, the welding process can be controlled, the focusing spot is small, the positioning accuracy is high, and it is easy to realize automation.

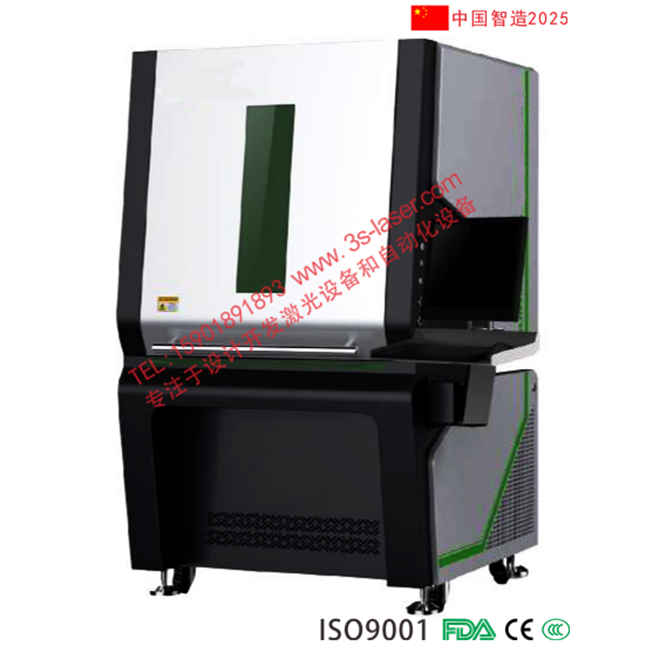

Features:

1. Real-time energy control, various waveform settings, bring precision welding quality

2. High stability, high stability, 24-hour stable operation

3. The welding spot energy distribution is uniform, suitable for complex welds and device spot welding

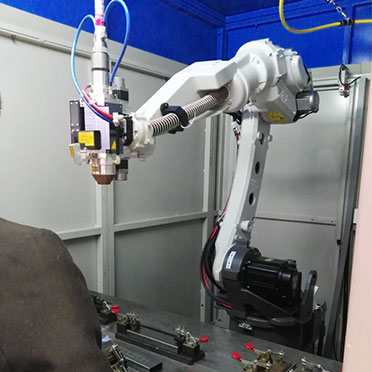

4. It can realize the trajectory control of welding points, straight lines, circles and other planes and special-shaped graphics. The welding programming adopts trajectory programming, the operation is simple, the welding process is automated, the welding program can be modified, and the operation and modification authority can be set; 5. High electro-optical conversion Efficiency, good beam quality, low maintenance cost, a replacement for existing lamp-pumped YAG lasers

6. CCD monitoring system, X/Y/Z/U worktable, rotary worktable, automatic tooling and fixture, provide perfect processing scheme

Applicable industries:

Used in precision welding of metal sensors, metal shells, kettles, metal parts, auto parts, aerospace, pressure vessels, military industry, sheet metal processing, metallurgical steel rolling, petroleum, machinery, pipes, etc.