introduce:

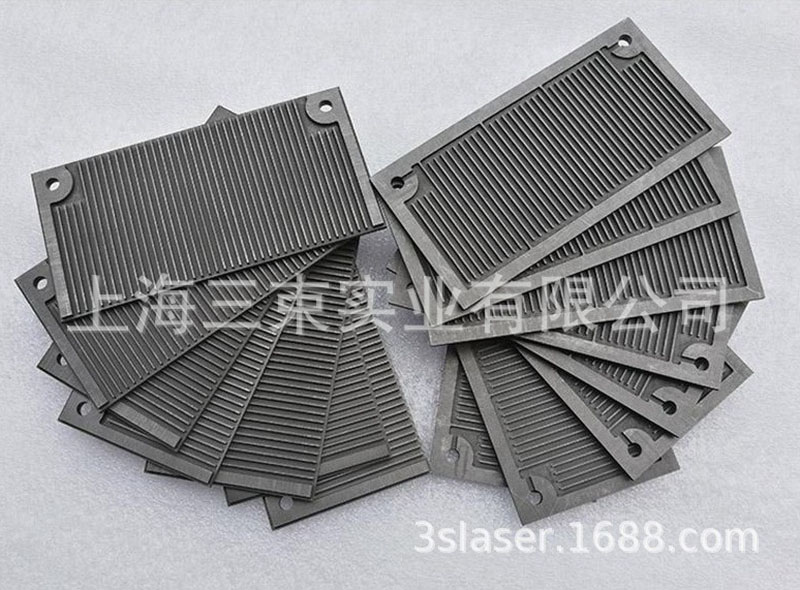

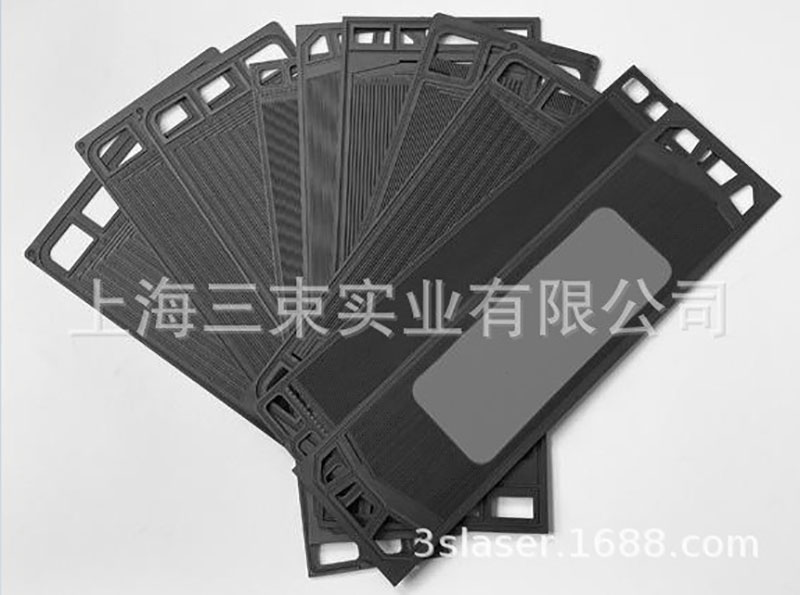

As a heat source for welding, laser has the advantages of excellent collimation, high beam energy density, small action area, fast temperature increase, and fast condensation. During the welding process, the light beam generated by the laser is applied to the area to be welded through the optical path system composed of optical fibers, one layer is a light-transmitting layer, and the other is an absorbing layer; The plastics are melted into each other, and during the subsequent solidification process, the melted material forms a new mutual fusion material, which connects the welded parts.

Features:

1. Low deformation caused by heat conduction

2. There is no concern of pollution or damage, it is not a contact welding work, and the loss and deformation of the welding head can be reduced

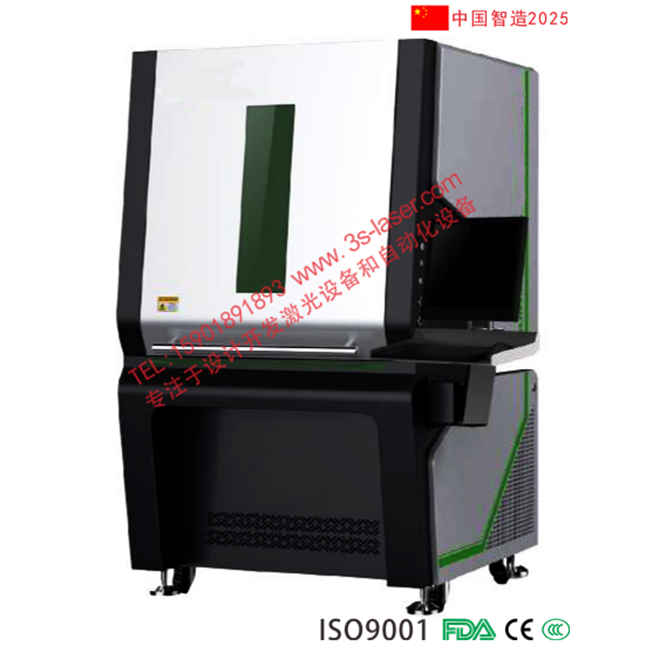

3. Adopt air-cooled heat dissipation. Increased device stability and light quality

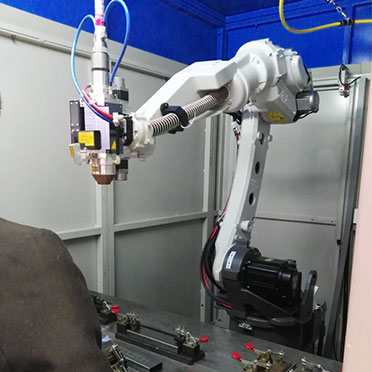

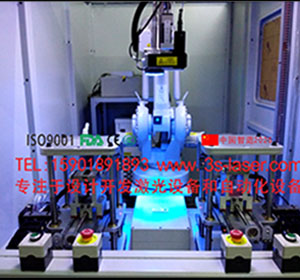

4. The laser beam can be focused in a small area, and can weld small and closely spaced parts

5. The system is easy to operate and stable, using LCD display as the man-machine interface, the operation is intuitive and simple; it can weld a variety of different plastics together

6. High automation integration, online welding can be realized

7. Not affected by magnetic fields (arc welding and electron beam welding are easily affected), and welding of aligned weldments

8. Excellent welding quality and high machining accuracy

9. Good applicability

Applicable industries:

It is used for welding optical fiber connectors, microelectronic components, instruments, precision parts, etc. It is suitable for plastic welding applications. Used in home appliances, automobiles, computers, communications, aerospace and electronics industries.